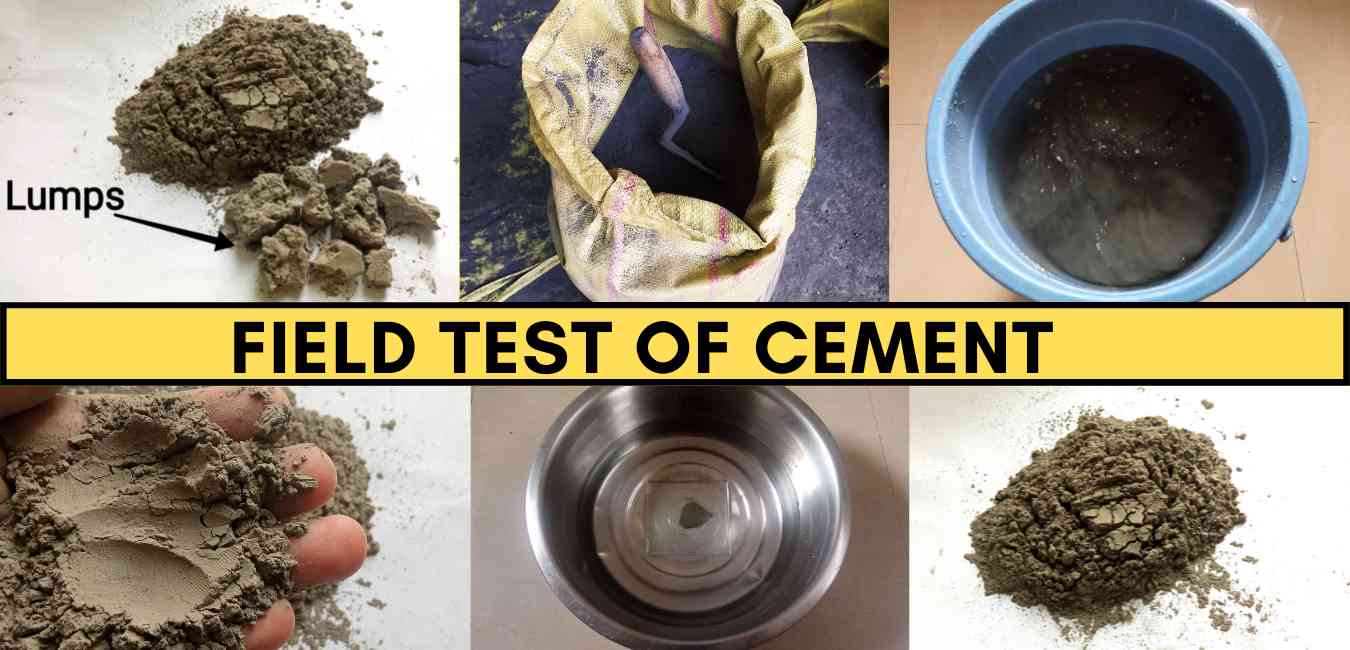

In this article, we are going to learn various field tests of cement and how to perform these tests to check the quality of cement on construction sites.

Table of Contents

Field Tests of Cement –

1) Date of packing.

2) Colour Test.

3) Rubbing Test or Adulteration Test.

4) Temperature Test.

5) Presence of lumps.

6) Floating Test.

7) Smell Test.

8) Cement Setting Test.

9) Cement Strength Test.

Importance of Field Test of Cement –

The quality of construction depends on the quality of materials used in construction. And as we know cement is the main material in the construction industry. When cement is stored on-site it may be affected by atmospheric conditions and other factors.

Cement used for construction should be of good quality and to ensure the quality of cement it is necessary to conduct field tests of cement.

9 Field Tests of Cement to Check Quality of Cement on Site –

1) Date of packing –

The first thing to do in the field test of cement is to check the date of packing of cement bags.

A study on cement shows that the quality of cement is decreased by 20-50% with time.

Cement Age | Reduction in Strength of Cement |

| 3 Months | 20-30% |

| 6 Months | 30-40% |

| 9 Months | 40-50% |

So as per the above study to get a good quality of cement, it should be used before 90 days from the date of packing of cement bags.

2) Colour Test –

Take some amount of cement from the cement bag and check the colour of the cement. The colour of cement should be uniform and it should be grey in colour with a light greenish shade.

3) Rubbing Test or Adulteration Test –

Take a small amount of cement in hand from the cement bag and rub it with your fingers. If it feels smooth then it indicates the good quality of cement and if it fell rough it indicates the adulteration in cement.

4) Temperature Test –

In this test, insert the fingers in a cement bag and check their temperature. Cement should feel cool and if it feels warm it indicates the hydration of cement is starting in the cement bag.

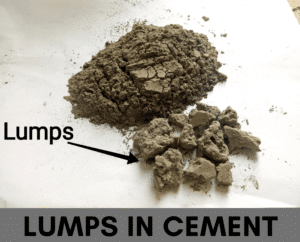

5) Presence of lumps –

Moisture is not good for cement. When cement is reacted which moisture it undergoes a chemical reaction and forms lumps in cement. So it is required to check cement for the presence of lumps before its use in construction.

Cement should be free from lumps and if lumps are present in cement it indicates the presence of moisture and such cement should not be used for construction.

6) Floating Test –

Take water in a bucket and throw a small amount of cement on the water. The cement should be float for a while before sinking into the water.

7) Smell Test –

Take a small amount of cement sample and smell it. If it gives an earthy smell then it indicates the adulteration in a high quantity of pounded silt and clay in cement.

8) Cement Setting Test –

Take a small sample of cement from a cement bag and mixed it with water to form a paste. Put this paste on a glass plate and submerged this glass plate in water for 24 hours.

Check the cement paste after 24 hours, it should be set, not crack.

9) Cement Strength Test –

- Take some amount of cement and add some amount of water in it to make a paste.

- Now fill this paste in mould to make a block of cement of size 25mm breadth, 25mm height and 200mm long.

- Now submerged this cement block in water for 7 days.

- After 7 days take out cement block from water and place it on supports with span of 150mm.

- Now, load the cement sample with a weight of 34kg.

- After loading if cement block does not shows any failure means quality of cement is good.

FAQ on Field Test of Cement –

1) How to avoid lumps in cement?

To avoid lumps in cement bags we can do –

- Store cement in waterproof shades and this shades should be above ground level to avoid moisture effect from ground.

- Cover cement bags with waterproof covers to protect it from atmospheric moisture and accidental sprinkle of water.

2) How many months old cement can be used?

Cement should be used before 3 months from its manufacturing date.

Very usefull

Excellent stuff which are useful for civil engineering thank u for providing these

Thankyou for excellent in which useful