Table of Contents

What is initial and final setting time of cement?

Setting time of cement is an important property to knowing the time limit for handling, transportation and placing of concrete. Setting time of cement is divided into two types-

- Initial Setting Time of Cement.

- Final Setting Time of Cement.

But before discussing these types let’s understand what is a setting of cement is?

What is the setting of cement?-

When water is added to cement it reacts with water and forms a paste. This cement paste is in a plastic state and can be moulded to any shape. After some time this cement paste starts losing its plasticity and starts to set. This entire process is called the setting of cement.

What is Initial Setting Time of Cement?

Initial setting time is a time from the moment water is added to the cement, to the time that the paste starts losing its plasticity.

Initial setting time of ordinary portland cement (OPC) is 30 minutes.

What is Final Setting Time of Cement?

The time from when water is mixed with cement to the time when cement paste loses completely its plasticity and became hard is called the final setting time of cement.

Final setting time of ordinary portland cement (OPC) is 600 minutes.

Significance of Initial and Final Setting Time of Cement –

- Initial setting time of cement gives us an idea about the time limit for handling, transportation and placing of cement on site.

- After placing cement on site it should not be disturbed up to the period of final setting time of cement.

- The final setting time of cement plays an important role in the formwork removal period of any structural member.

How to Calculate Initial Setting Time and Final Setting Time of Cement-

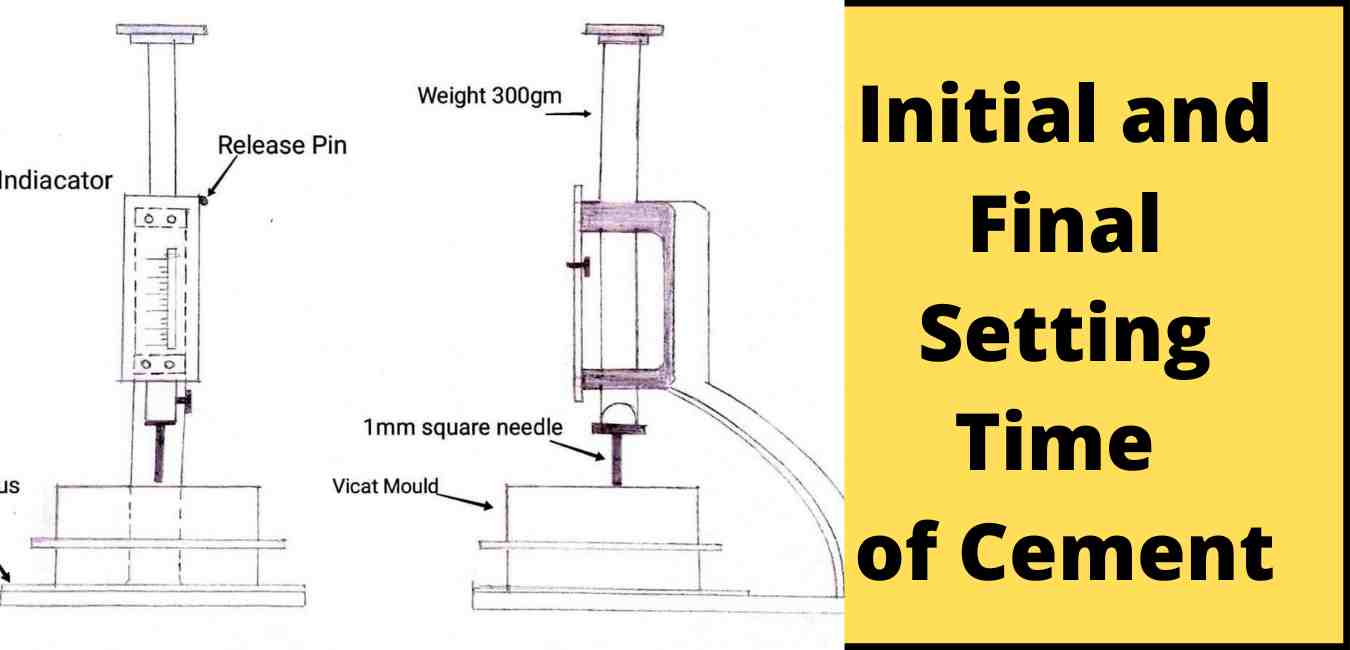

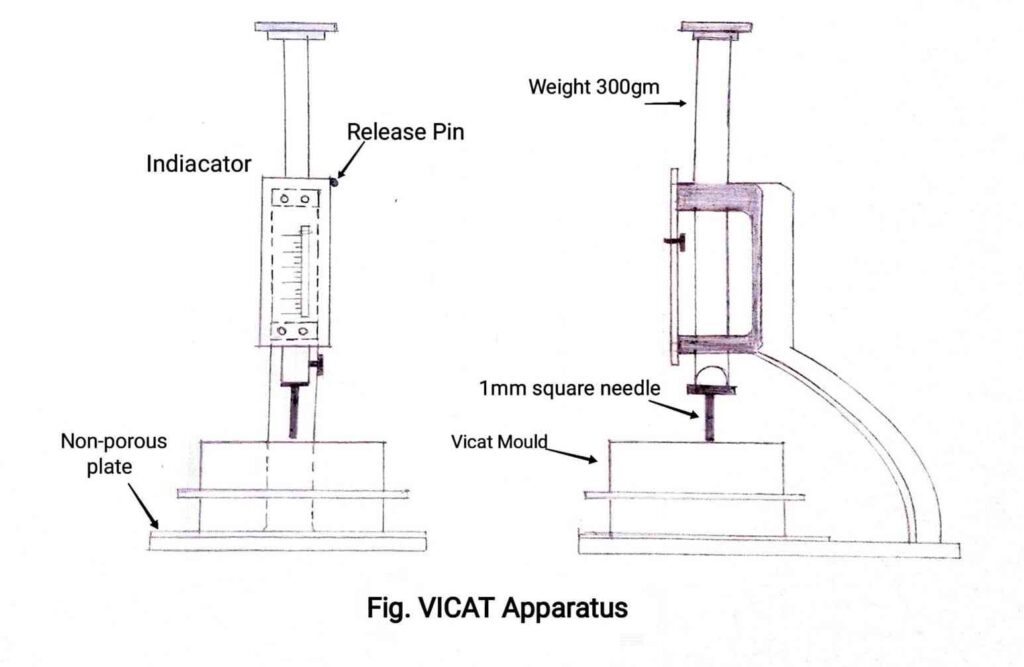

We are going to do a setting time test on cement using VICAT Apparatus as per IS 4031(Part 5):1988

APPARATUS-

VICAT Apparatus conforming to IS : 5513-1976.

VICAT mould

Measuring Cylinder of 200ml

Weighing balance with 1g accuracy

Stopwatch

Trowel

Procedure to Find Initial Setting Time of Cement –

1) Take 500g of cement in-tray.

2) Add the amount of water (which is calculated using the formula given below) to cement to make cement paste and start the stopwatch. ( Stopwatch should be started from the moment water is added to the cement).

Amount of water to add = 0.85P % of the weight of cement.

Where P = Percentage of water required to make a cement paste of standard consistency.

3) Pour this cement paste into the Vicat mould using a trowel within 2-3 minutes from water added to cement and level the top surface properly.

4) Then place this mould on the Vicat apparatus under the square needle.

5) Move the needle slowly downwards until the needle touches the top surface of the mould.

6) Then released the square needle and allow it to penetrate into the mould.

7) Now note down the reading on the Vicat scale, initially, it shows zero reading because the needle completely penetrates into the mould.

8) Repeat this procedure at 2 minutes intervals until the Vicat scale shows a reading of 5mm (which means the plunger should stop penetrating 5mm from the bottom of the mould).

9) Now note down the time shown on the stopwatch. This time from the moment water was added to cement to the time needle penetrated the cement mould 5mm from the bottom is the initial setting time of cement.

Procedure to Find Final Setting Time of Cement –

1) Replace the needle of Vicat apparatus by needle with angular attachment.

2) Move the needle slowly downwards until it touches the top surface of the mould gently.

3) Then released the needle and allowed angular attachment of the needle to make an impression on the top surface of the mould.

4) Now repeat the same procedure at some time intervals until the angular attachment of the needle is failed to make an impression on top of the mould.

5) Note down the time shown on a stopwatch. This time from the moment water is added to the cement to the time at which the circular attachment of the needle failed to make an impression on the surface of the mould is called the final setting time of cement.

Calculations –

Weight of cement sample = …….. gms.

Water required to make cement paste of standard consistency = P = …….. %.

Quantity of water added = 085P = ……. ml.

| Sr.No | Time | Reading(mm) |

The initial setting time of the cement sample is ………..

The final setting time of the cement sample is ………….

Precautions –

- Lumps should be removed from the cement sample.

- Test should be performed away from any vibrations and disturbance.

- The room temperature should be maintained at 27 ± 2°C at the time of conducting the initial and final setting time of the cement test.

- The relative humidity of the laboratory should be 65 ± 5%.

- The needle should be released gently.

Initial and Final Setting Time of Cement of Different Grades –

| Type of cement | Initial Setting Time (min) | Final Setting Time (min) |

| Ordinary Portland Cement | 30 | 600 |

| Portland Pozzolona Cement | 30 | 600 |

| Quick Setting Cement | 5 | 30 |

| Rapid Hardening Cement | 30 | 600 |

| High Alumina Cement | 30 | 600 |

| Sulphate Resisting Cement | 30 | 600 |

| Super Sulphated Cement | 30 | 600 |

| Portland Slag Cement | 30 | 600 |

| Hydrophobic Cement | 30 | 600 |

| Low Heat Cement | 60 | 600 |

| Masonry Cement | 90 | 1440 |

FAQs on Initial and Final Setting Time of Cement-

What is the initial and final setting time of ordinary portland cement(OPC) of different grades?

| OPC Grade | Initial Setting Time | Final Setting Time |

| Grade 33 | 30 | 600 |

| Grade 43 | 30 | 600 |

| Grade 53 | 30 | 600 |

Which IS CODE is used to find initial and final setting time of cement?

The initial and final setting time of cement is calculated using the VICAT apparatus as per IS 4031(Part 5):1988.

What is the difference between the setting and hardening of cement?

The setting of cement is the stiffening process of cement paste. When we add water to the cement sample it forms a paste. This cement paste is in a plastic state. The transformation of the cement paste from a plastic state to a solid state is the setting of cement.

After the setting of cement, it starts to gain strength, this strength gaining process is called the hardening of the cement.

Also, Read –