Table of Contents

Storage of Cement Bags on Site–

Storage of cement bags on site should be done in a proper way. Because cement is climate-sensitive material and it reacts with moisture from the atmosphere and starts the hydration process which makes cement hard.

So there are some precaution should be taken for bulk storage of cement as per IS code 4082: 1996 as follows –

1) Sheds for storage of cement –

2) Arrangement of Cement Bags –

3) Storage Duration –

4) Protection in Rainy Season –

5) Handling of Cement Bags –

6) Use of Cement Bags –

1) Sheds for storage of cement –

On construction site storage of cement should be done in a proper way so they are not exposed to the atmosphere and can be stored for a long time before being used in construction.

Bulk Storage of cement bags on site should be done in buildings or closed sheds whose floor, roof, and walls should be dry, leakproof, and moisture-proof.

The building or shed should have a minimum number of windows and doors. The windows of these sheds are must be small in size and the door should be airtight and kept these doors closed as far as possible.

Proper drainage should be provided for the drainage of water in any case.

2) Arrangement of Cement Bags –

Before the storage of cement bags on site ensure that the shed is completely dry from inside.

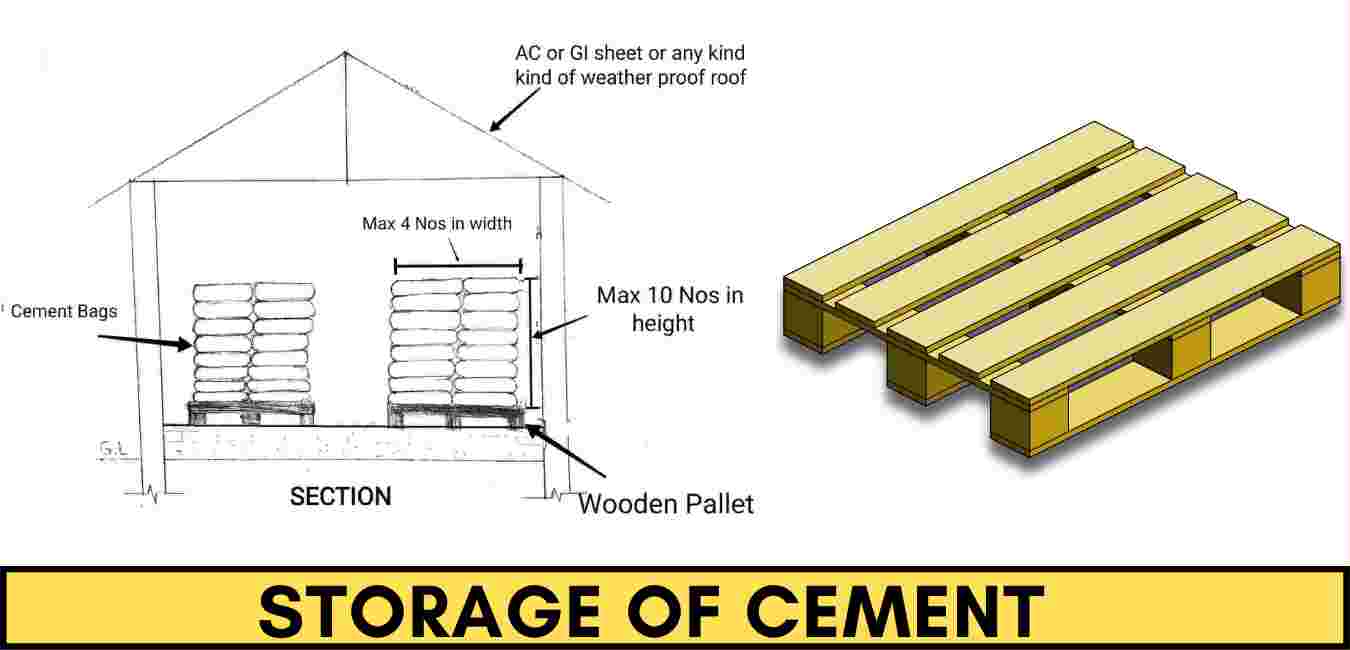

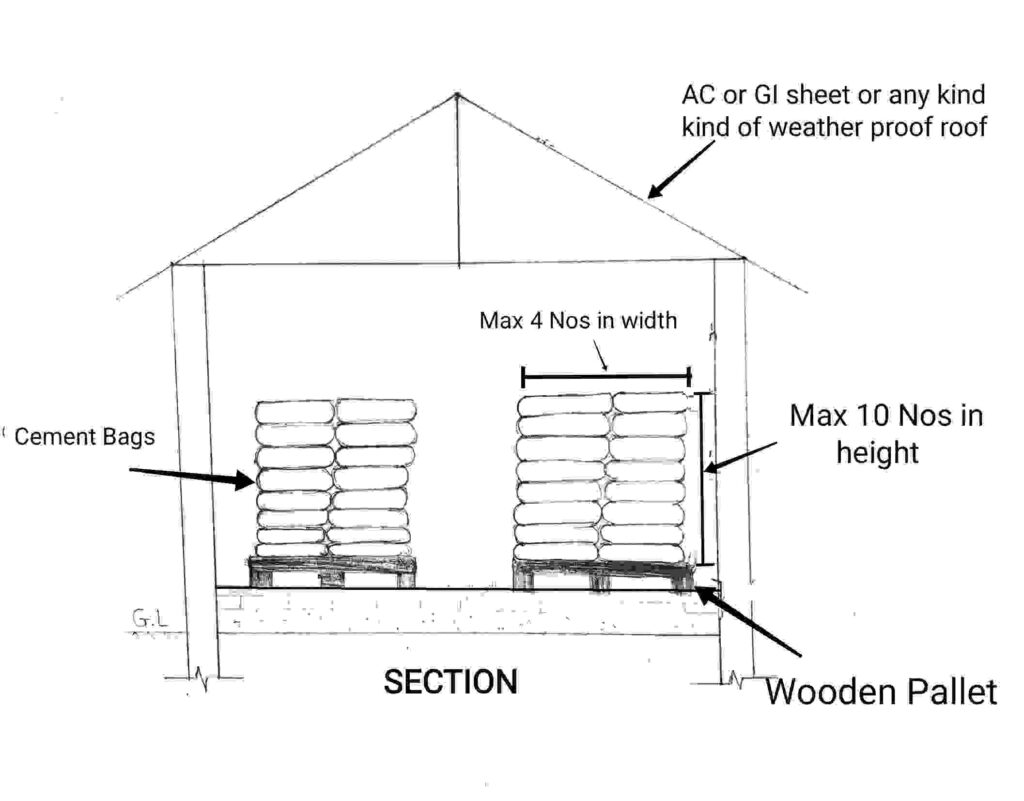

Dampness is also responsible for the moisture in cement. So, the cement bags should be stored on wooden pallets in such a way that as to keep about 150mm to 200mm above the ground level.

Cement bags should be arranged one above the other in a cross arrangement in length-wise and cross-wise fashion to minimize the danger of toppling over.

The arrangement of cement bags should be closed to each other to avoid air circulations.

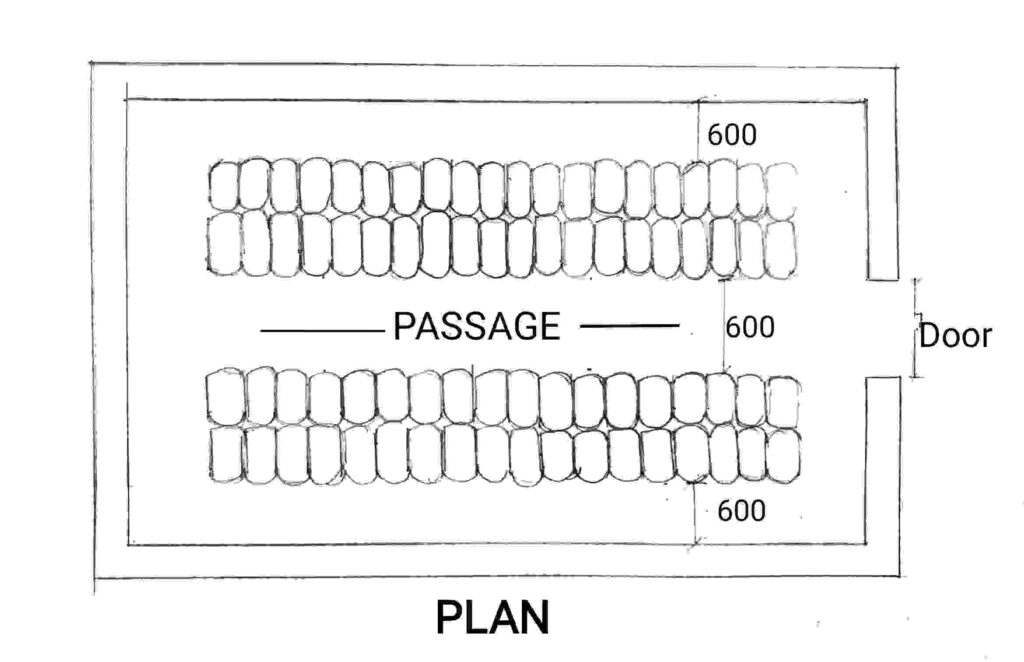

Stacked bags should be at least 600mm away from the external walls.

These stacked cement bags should not be more than 10 bags in height to prevent the possibility of lumping up under pressure and the width of the stack should not be more than 4 bags or 3 meters.

Different types of cement should be stored separately.

Different types of packaging bags should be stored separately such as paper bags, gunny bags, and polyethylene bags, etc.

A passage width of 600mm should be provided for easy access.

3) Storage Duration –

Time is also an important factor in the storage of cement. Because the strength of cement is decreased with time.

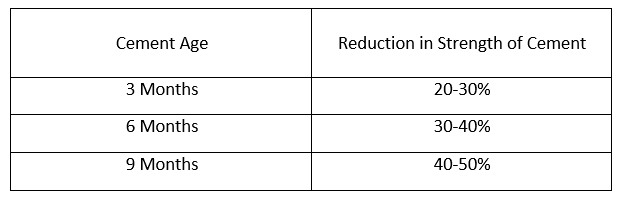

The table below shows the percentage of decrease in strength of cement with time –

So, Cement should be used before 3 months from the date of manufacturing.

If cement is stored for more than 3 months duration then it is recommended to cement should be tested before using it on site.

4) Protection in Rainy Season –

During monsoon season extra moisture is present in the atmosphere which required extra precautions for the storage of cement.

In the rainy season, cover the stack cement bags with plastic sheets or tarpaulins to protect them from moisture and an accidental sprinkle of water.

5) Handling of Cement Bags –

Do not use hooks while handling cement bags in loading and unloading.

Do not drop cement bags from height as this can damage the packing of cement.

Handle cement bags with care to avoid split of bags and damage of packing.

6) Use of Cement Bags –

Cement bags should be used on a first in first out basis. This means cement bags that are stored first in sheds should be used first for the construction.

A label of the date of receipt of cement should be put on each stack to know the age of cement.

FAQ on storage of cement bags on site –

How long cement can be stored?

It is recommended that cement should not be store for more than 3 months.

How much area required for storage of cement?

Approximately, in 1 cubic meter, 20 cement bags of 50kg each can be stored.

Also, Read – How to Check Quality of Cement on Site